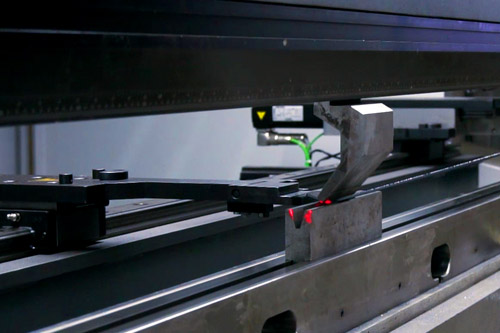

Bending

Bending is a method of bending flat plate work piece. This step comes in production process straight after cutting. Work piece lays on the matrix with a hole in the V shape. Wedge-shaped tool (punch) presses the work piece into the V shaped hole and by this process it bends it into required angle.

Advantages:

- ACCURACY – to ensure maximal precision the bending the bending press uses hydraulic dynamic camber. The punch and matrix are purposefully curved. This leads to compensation of the deformation, which occurs during bending process. In such way the exact and constant bending results are obtained even in case of bending parts of 3 m length.

- SPEED – during point-to-point bending the punch presses the work piece into the hole in the matrix, but not to the bottom of the matrix. The work piece lays only on both edges of the matrix during the whole bending process. The angle of bending is given by the punch and how deep it goes into the matrix. Point – to –point bending enables to bend different angles without necessity to change the tools.

Technology specification:

- Bending press capacity 50 – 220 Tons

- Bending length 1,600 – 4,100 mm

- Installation height 430-580 mm

- Standard stroke 150 – 300 mm

- Maximum working feed 140mm/s

- Maximum working speed 10mm/s