High quality machining method of wild range of materials that enables fast and exact cutting with maximal performance and minimal individual costs. Number and varieties of automating solutions and smart modes provide maximal utilization of the machine and also ensure reliability of the process of cutting itself.

Modern, high-quality and ecologic method of machining of the whole range of materials.

High-pressure device enables to compress water up to 4,150 bars. Abrasive material is mixed into water jet in mixing chamber. This mixture is afterwards ran through the one millimetre jet.

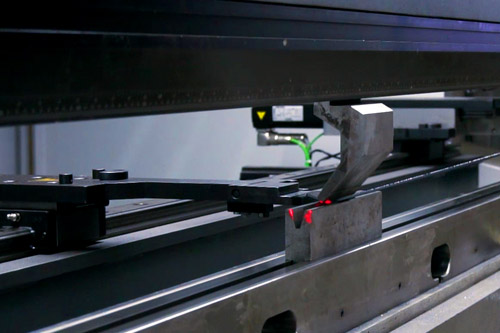

Bending is a method of bending flat plate work piece. This step comes in production process straight after cutting. Work piece lays on the matrix with a hole in the V shape. Wedge-shaped tool (punch) presses the work piece into the V shaped hole and by this process it bends it into required angle.

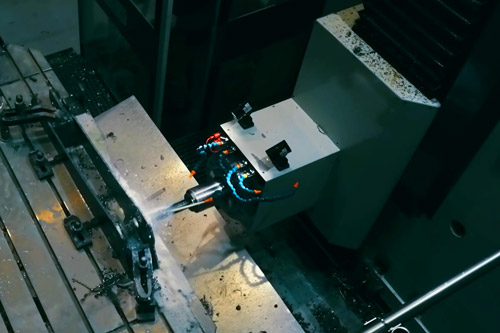

This machine is milling and drilling table machine with cross shear set up. Machine construction offers wide range of varieties in all parameters and enables to select optimal configuration of the given product. Horizontal drilling table machines offer the possibility of effective machining with high milling capacity and accuracy.

- we offer production of scalds using the MIG, MAG TIG methods

- measurements and quality are done as tests – VT2, PT2, MT2, LT2, UT2

- formation of the welding process WPS and WPQR

- certification EXC2 and EXC3